Our Energy Future: Carbon Capture & Storage

Read time: 4 minutes

Read time: 4 minutes

The UK government has outlined plans to develop a competitive carbon capture and storage (CCS) market by 2035. Here, we explore the practicalities of CCS technology and how the market is shaping.

CC involves capturing carbon dioxide and storing it underground before it’s released into the atmosphere. It’s being suggested as a solution for reducing emissions generated as a result of oil and gas extraction and other industrial processes.

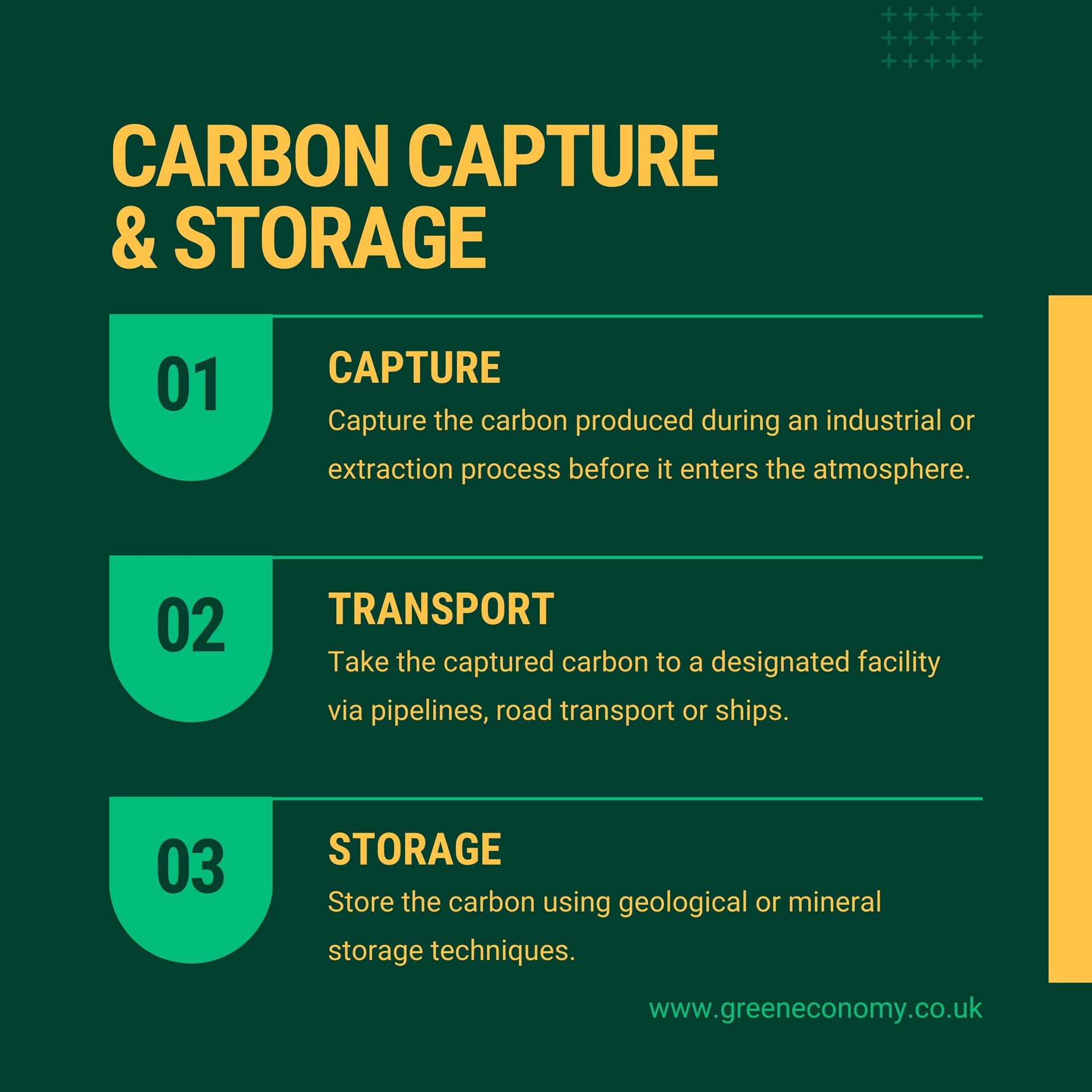

The process has three steps.

For the final step, the two primary methods of storage are geological or mineral storage. Deep ocean storage of CO2 will increase ocean acidification which is a negative impact of carbon emissions. Geological formations are the most promising sites for storage at and offer a considerable amount of space. If a geological site is managed and structured effectively, CO2 could be trapped for millions of years with 99 per cent of CO2 being retained over the first 1,000 years, according to the IPCC.

Mineral storage has also shown promising results. It works by reacting captured CO2 with naturally occurring iron, magnesium and calcium for long term storage. These minerals are abundant and stable, but the carbonation process is very slow and would require energy intensive conditions to speed up the process.

CO2 is a by-product of burning fossil fuels. Capturing this CO2 to prevent it from entering the atmosphere can be broken down into three types of capture, technological, biological, and geological.

Technological carbon capture involves man-made solutions to capturing and storing carbon, such as direct air capture in cities, and carbon capture at power plants, tackling emissions from their source. Carbon capture in power plants can be broken down into three key techniques

Large air filters are being trialled in cities and work by drawing air into glass rooms, heated using solar power to create a greenhouse effect. The hot air is then pushed through a series of filters before being released back into the atmosphere as clean air.

Involves removing carbon from a fuel before combustion takes place. This works by oxidising a fuel before use which converts the fuel into a gaseous mixture of hydrogen and CO2. The hydrogen is then separated and burned without producing CO2. Pre-combustion techniques are more complex and difficult to apply to existing power plants.

For this process, fuel is burned as normal with carbon captured through chemical absorption, using a liquid solvent or other separation methods. It involves absorbing carbon from the flue gas in a separation tower which is regenerated by heating in a recovery column. You then end up with a high purity CO2 steam which can be captured and stored.

This type of carbon capture can be more easily applied to already existing power plants and is a more developed and tested form of carbon capture.

This involves using oxygen rather than air for combustion of the fuel. This produces an exhaust gas which is primarily water vapour, meaning the CO2 can easily be separated to create high purity CO2 steam.

Biological carbon capture refers to natural forms of absorbing and storing carbon, known as carbon sinks.

Carbon sinks include vast spaces of natural habitats, such as forests, grasslands, and oceans. Of these three, coastal wetlands are able to store more carbon per hectare than habitats like forests. The same goes for peatlands. A 15-hectare peat bog in South Wales stores 32,000 tonnes of CO2, equal to the annual emissions of 22,000 petrol cars.

Oceans are also great absorbers of CO2, absorbing an estimate 25 per cent of emitted CO2 from the Earth’s atmosphere. However, if the ocean absorbs too much carbon, it can acidify the water which poses a threat to marine biodiversity, such as coral bleaching.

Carbon sink projects are commonly used in offsetting projects, for example when an organisation pledges tree planting and reforestation to offset their carbon emissions.

Geological carbon capture refers to carbon stores within underground formations or rocks. Carbon that has already been captured can be injected into rocks at depths of 1 – 2.5km, trapping the carbon for centuries.

The most obvious benefit of CCS is that it prevents carbon from entering the atmosphere and contributing to global warming. Operations that generate carbon emissions can be coupled with CCS to reduce the negative impacts of these, making it a solution for emissions-heavy operations that we do not yet have alternatives to. What's more, certain types of CCS can remove other pollutants from the atmosphere in the process. During oxyfuel combustion, high concentrations of oxygen used for combustion leads to a significant reduction of nitrogen oxide and sulfur dioxide gases.

Once the carbon has been captured, it has other applications. The carbon can be used to manufacture polymers and polyurethanes, and to reinforce concrete for more durable infrastructure. It can also be used as a means of generating geothermal energy as geologically stored carbon dioxide might be utilized tocan retrieve geothermal heat from the area injected, resulting in the generation of sustainable geothermal energy.

CCS requires construction, engineering, and maintenance professionals to ensure it works effectively to deliver on carbon abatement, creating a market for green jobs in the UK. Engineers are able to specialise in CCS and move away from fossil-fuel roles to take up work with a firmer focus on climate.

Despite investment into the CCS sector, critics argue it does nothing to reduce carbon emissions at their source with environmentally damaging processes such as oil and gas extraction. There are concerns that CCS will be used as an excuse to continue with destructive fossil fuel production, with some campaign groups even calling CCS “greenwashing.”

CCS isn’t occurring at anywhere near the scale needed to balance CO2 emissions. The Energy Agency has calculated an “implausible” 32 billion tonnes of CO2 would need to be captured each year by 2050 to balance out the carbon emissions generated from oil and gas extraction. A clean energy transition away from fossil fuels in favour of renewable technologies will reduce the amount of carbon entering the atmosphere from its source and should be considered before.

CCS is also a nascent technology and more research is needed to guarantee its effectiveness. Initially, storage processes will require rigorous monitoring to ensure the right quantity of CO2 is being storage, there are no carbon leaks, and to ensure the CO2 is behaving as anticipated while in storage.

As for the costs, CCS is presently an expensive and research-intensive practice, but costs are forecasts to decline as investment increases and the processes reach their commercial maturity. The storage process is also characterised by complex design and regulatory environments, with difficult technological processes generating high risks of bottlenecks and dead ends which could be financially wasteful.

In the 2023 Spring Budget, the UK government committed to investing £20bn to scale up UK CCS projects. This roadmap details up to £210m for the Industrial Strategy Challenge Fund, £115m in new spending for CCS technology research and development, an estimated turnover of £8bn by 2050 secured by the UK CCS market, a target to capture 20 – 30 MtCO2 per year by 2030, and the creation of 50,000 jobs in 2030.

Since this announcement, the UK government has pledged nearly £22bn for CCS projects. The move is expected to create thousands of green jobs and help the UK meet its greenhouse gas targets.

The government hopes the move will attract £8bn in private investment, directly creating 4,000 jobs and support a further 50,000 in the long term, helping remove 8.5 million tonnes of carbon from the atmosphere each year. Of the investment, £21.7bn will be injected into three projects across Teesside and Merseyside, supporting the development of CCS clusters.

Before you can start your journey to net zero, it is important to understand where you are starting from. This guide explains all you need to know about carbon footprinting and how to measure this in your business.

What is meant by ‘Scope 3’ greenhouse gas emissions, why they are important and how can businesses begin to measure them as part of their carbon footprint?

What is meant by climate change targets that are ‘science-based’, why are they important and how can businesses follow a science-based pathway in their own carbon reduction plans?

There are a dizzying number of environmental standards and accreditations available to businesses today. In this guide, we take you through the key products to help you identify the most appropriate option for your business.

Net zero - what is it, why should you care and what can your business do about it?

Research shows that the carbon footprint of the average supply chain accounts for 90 per cent of a business's carbon footprint. In this guide we explore the steps businesses can take to be a green supplier of choice.

One of the simplest ways for you to reduce your impact on the climate is to switch your energy supply to renewable electricity, read our step by step guide.

When looking to reduce emissions from your operation, carbon offsetting appears an attractive quick fix. Here we explore how carbon offsetting works, when it can be effective and why it should be the final item on your carbon reduction to-do list.

Understand the principals of ‘corporate greenwash’ and why businesses need to be accurate, clear and transparent when promoting their environmental credentials.

Share